I spent quite a bit of time getting the electronics running, so its finally time to bring the mechanical side of the printer up to speed as well. I do not like switching back and forth between different sections of a build, but doing so is unavoidable for this design as the mechanical and electrical components have been mixed together to keep the build compact.

The first alignment I'll be working on is X-Y squareness. Unlike other alignments which can be directly measured, X-Y squareness needs to be evaluated in two steps because there is no accessible reference surface to place the square against.

The first step is to place the square on the table and align it to the Y axis. I took quick video of the process to show how you can achieve very precise alignments with nothing more than a mallet. It seems counter-intuitive at first, but it is really quite easy if you have the correct measuring equipment.

Once you are confident that the square is aligned to the Y axis, align the X axis to the square. These two steps together complete the X-Y squareness alignment. I was worried about the square shifting (normally it can be bolted down when aligning machine tools), so I performed the complete alignment a second time to make sure it was correct.

The X axis tram/flatness alignment is very simple and ended up slightly better than +-0.001"

As with the previous bed alignment, this error is not linear which indicates that the bed is not flat.

In total I have performed five alignments, which is the full set required for a 3 axis cartesian robot.

- Y-Z Squareness (Z Stage Alignment)

- X-Z Squareness (Z Stage Alignment)

- Y Tram/Flatness (Bed Alignment)

- X-Y Squareness (This Post)

- X Tram/Flatness (This Post)

The extruder assembly bolts directly to the X axis stage.

The wires have enough compliance to accommodate the full range of travel.

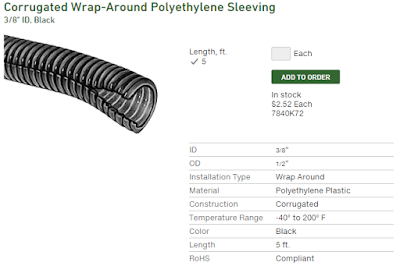

The printed cable holders are quite bulky because I was planning on covering the wires with corrugated sleeving but forgot to order it. I'll grab some with my next McMaster order.

In my next post I should be able to run the extruder wiring back to the Smoothieboard and finally start testing the printer.

No comments:

Post a Comment